Change Language :

Overengineering

The customer defines what is perfect. Understanding customer needs avoids over-engineering

Over-engineering refers to products with functions that cost time and money but offer the user no added value. It is also often referred to as "just-enough engineering". A prominent example: Juicero Press - a device that squeezes juice and vegetable bags from Juicero. The device was launched on the market in 2016 for USD 400. Only then did it become clear that juice fans were squeezing the bags by hand just as quickly. Juicero went out of business. This example makes it clear that a product that is perfect from a developer's point of view is not necessarily suitable for customers. It can also be the perfect waste.

Would you like to find out more about over-engineering and the possible solutions from igus®? Download the free white paper here.

Why companies do not cover their costs despite perfection

Ever better functionalities, more standards, modularity and a low total cost of ownership at a fair price: this is a brief and concise summary of what companies in all sectors expect from their machine and plant manufacturers and, in turn, from their part and component suppliers. As a result, the tension between engineering and controlling is growing. It is not only since yesterday that purchasing departments have been required to keep purchase costs for bought-in parts or modules low, for example. What many decision-makers are not aware of - despite the close dialogue with Purchasing - is that the choice of supplier has a decisive influence on costs. Studies [1] show that clients often generate additional costs when making a cost-driven decision between two suppliers.

However, there is also a phenomenon on the contractor side that has a negative impact on costs and can therefore jeopardise good business relationships that have developed between the service provider and the client: Over-engineering. This white paper looks at what lies behind it, what the possible causes are and what solutions are available.

Cost trap: planning past the specification

Many companies do not even have in-house over-engineering as a cost driver on their agenda at the start of product development. This can also be explained by the variety of interfaces - a technical dialogue between the client's engineers and the contractor's design engineers is by no means standard. This has consequences, because the product development process does not exist. Companies think in variations and are increasingly agile. Designers orientate themselves roughly to what is taught in mechanical engineering studies, for example [2]. For example, the product development process is based on the guidelines of the Scientific Society for Product Development (WiGeP) and is roughly divided into the following phases:

- Product planning (needs assessment, brainstorming, feasibility study)

- Product development (layout, design)

- Production (production planning, production, assembly, commissioning)

It is also noticeable that the product development process is too rarely considered as part of the product life cycle. The consequence: operation, maintenance and, last but not least, disposal or reuse or recycling of the product are not given sufficient consideration. This also promotes over-engineering. An example [3] from practice illustrates the consequences: An engineer had to optimise a production concept. It was a fully automated process in which a station inserts leakage sponges into an end product. This process does not require any particularly high force - a classic pick-and-place process. However, according to the engineer, the base frame, the yoke plate and the columns supporting the pneumatic axis were designed as if the sponge had to be pressed with 10,000 newtons. In the expert's opinion, a lighter and more favourable machine design would have been sufficient for the customer's requirements. The consequences: Additional material and design costs. Added value: none.

Without dialogue, design ideas are often too much of a good thing

It can be assumed that the dilemma could have been avoided through better communication. After all, whether a developed product actually fulfils all of the customer's requirements can only be precisely quantified after the sale and an evaluation of the sales figures and contribution margins. Although software tools, analyses and assumptions provide support in the planning phase, there is no certainty until after commissioning and successful production.

This is a fine line for companies: they must neither develop without taking the customer's needs into account nor stop trying to improve their technologies.

It is now recognised that precise knowledge of customer requirements is needed to avoid over-engineering. Only by identifying the customer's interests can you avoid investing time and resources in the wrong developments. Simulation tools or so-called conjoint analyses can help.

The trend: customer surveys capture needs

Case studies [4] make it clear that a clever system for evaluating customer requirements is essential in order to counteract the continuous cost pressure [5]. Based on this, the motion plastic specialist igus® has carried out an internal analysis in its target markets with the aim of developing even closer to customer requirements and avoiding over-engineering. Benefit for the industry: either the costs fall or there is more technology for the same amount of investment. By adjusting the parameters and understanding customer needs and regulatory requirements, the total cost of ownership for the end customer is reduced in the best case scenario.

The cross-industry survey conducted by the motion plastic specialist's business development and product managers shows which factors are most important to customers when purchasing components and machines:

- the stability of a product and the resulting longer service life

- saving even more installation space when implementing a component in the machine

- reduce the noise level on a system or in production

- reduce the weight of a product

- Reduce assembly times for installation on a system

- Minimise maintenance costs/intervals for components/parts and therefore for the machine

- Reduce the total cost of ownership (procurement, operation, maintenance, disposal)

Surprising results and diversity of variants between industries

Technical decision-makers from all sectors emphasised stability and service life. However, the engineers surveyed from the construction machinery, railway and offshore sectors were not aware of the importance of stability and service life. For example, the required installation space of a component is rather unimportant, which is only plausible given the size of the system.

When it comes to noise development, engineers in the medical technology, automotive and aerospace sectors attach particular importance to perfection, while it plays a rather subordinate role for the other respondents. Industries in which noise is irrelevant benefit from established standard components with a good price-performance ratio.

The same applies to weight: while it plays a central role for designers in aerospace technology, it is a secondary factor for engineers in other sectors. Here, too, the end customer can save costs in purchasing and consciously counteract over-engineering on the part of igus®. It is astonishing that for almost half of all companies surveyed from the 25 industries analysed, the issue of assembly time is less important and maintenance intervals also play a rather subordinate role.

Conclusion

The topic of over-engineering has arrived in the industry. Instruments such as the conjoint analysis support clients and service providers alike in treading the fine line between technical perfection and cost-efficient production. Industrial companies and suppliers can only survive the increasingly tough global competition if they concentrate on their core competences. This also includes actively seeking out and avoiding over-engineering.

However, not everywhere: in medical technology, for example, many products/technologies are used directly on or in people. Perfection, attention to detail and a little bit more safety even have priority here. This is where industry experts really appreciate over-engineering.[6]

[1] https://www.maschinenmarkt.vogel.de/sparen-im-einkauf-verursacht-erhebliche-mehrkosten-a-864291/

[2] Werner Skolaut (ed.), Mechanical Engineering, Springer Verlag

[3] https://www.wirtschaftswissen.de/einkauf-produktion-und-logistik/produktionsplanung/qualitaetsmanagement-produktion/schluss-mit-overengineering-warum-sie-stets-auf-adaequate-technologien-und-prozesse-setzen-sollten/

[4] https://www.tcw.de/news/optimierung-der-produktspezifikation-mittels-der-conjoint-analyse-980

[5] https://www.pwc.de/de/pressemitteilungen/2020/deutscher-maschinenbau-ist-und-bleibt-auch-2020-im-krisenmodus.html

[6] https://www.ingenieur.de/karriere/arbeitsleben/arbeitssicherheit/over-engineering-fuer-vorteil/

A product is only as good as a customer rates it.

▼Reduce costs

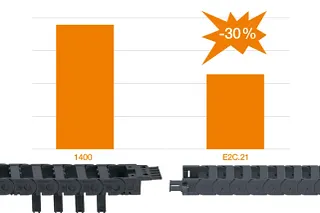

More stability, the same dimensions and a 30% price saving.

The E2.1 family is the successor to the proven E2/000 e-chain® family. All E2/000 e-chain® can be opened in the inner or outer radius. There are applications where opening and closing the chain is not necessary and money can now be saved. The E2.1 family is available with inner and outer radius opening, and also as a non-opening version. A lot of money can be saved quickly with the same dimensions.

▼Reduce costs

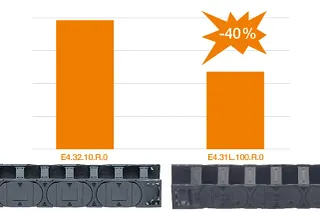

Save 40 % in price with almost identical e-chain® dimensions.

The E4.1 system is the robust and largest e-chain® family in the igus® programme. It impresses with numerous design tricks that are primarily focussed on high stability and modularity. The E4.1L (L=lean) family adopts many of these tricks, but the series is designed to be easier to assemble, lighter and more attractively priced.

▼Reduce costs

Save up to 50 % in price with cost-effective robot components.

Various Robotics clamps from igus® can be used to securely fasten the energy chain or the protective conduit to the robot. A lot of money can be saved quickly with simple solid plastic holders.

▼Reduce costs

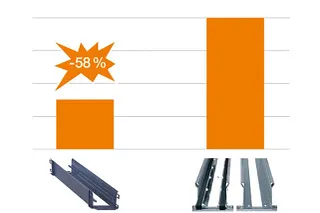

Save 58% on costs by using an acid-resistant plastic channel instead of stainless steel

Guide systems made of metal harbour the familiar problems: corrosion, complex installation, high weight and high costs. The material of the Guidelite-plus-EG guide trough ensures high chemical resistance, making it ideal for use in electroplating and fertiliser production. Due to its light weight and modular design, installation is significantly simplified.

▼Reduce costs

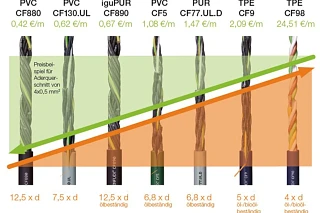

Save 64.7 % on control cable by dispensing with PUR and the CF130.UL.D

With the chainflex® price check, you can quickly find the right cable for your needs. Each electrical specification is available in 7 cable qualities. You have the choice: favourable price or the cable for high technical requirements. Thanks to this wide range of cables, we can offer you great cost savings for every type of cable; for example, a price advantage of 64.7 % for control cable with the favourable CF130.UL.D instead of the typical PURcable (CF77.UL.D).

▼Reduce costs

Ready-to-install savings: reduce storage costs for cable, e-chain® and connector to zero

Thanks to our just-in-time delivery, there is no need to store highly flexible cables, the corresponding connectors and any other attachments. igus® supplies pre-assembled readychain® systems that are customised for each application and can be installed on site in a final step.

With readychain® you receive a system solution in which all the components used are harmonised with each other. Each system is tested on our test stands before delivery.

▼Reduce costs

With readychain®, the number of suppliers and orders is reduced by 75%

With us, you can order entire systems with just one order number and also save valuable assembly time.

One order, one invoice, one delivery, one partner. Instead of procuring a large number of individual parts from different suppliers, we provide you with everything from a single source. We take over the procurement of the optimum individual parts for you at favourable prices and accompany your project from A to Z.

▼Reduce costs

Saving thanks to solutions for condition monitoring and predictive maintenance

Intelligent maintenance in the age of Industry 4.0: smart plastic from igus® can increase the reliability of machines, plan maintenance work precisely and thus save costs.

▼Reduce costs

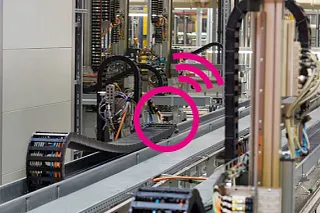

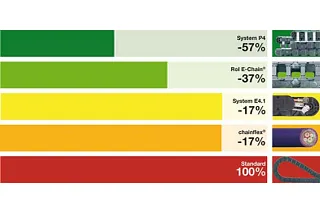

Save drive power - reduce energy costs

Energy chain systems not only transport energy, data and media to machines and systems. They also influence their energy costs. How much push-pull force, i.e. drive power, is required to move an energy chain at a given speed? Smaller and lighter energy chains with identical stability or roller energy chains can help here.

▼Reduce costs

Machine downtime - wasted money

Machines must function safely and without malfunctions. This requires a reliable energy chain system and cable. igus® assembly services avoid machine downtimes.

Consulting

I look forward to answering your questions

Hitech UAB (Distributor)+370 37 323271Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr