Change Language :

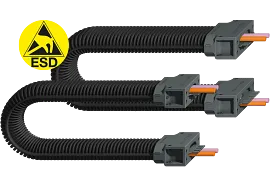

ESD energy chains

You can find these ESD energy chains on this page:

E2/000 ESD

Two-piece energy chains for a wide range of applications

Series 1500 ESD

Inner height hi: 21mm

Inner width Bi: 15 - 80mm

Bend radii R: 38 - 145mm

Pitch: 33.3mm

Series 2500 ESD

Inner height hi: 25mm

Inner width Bi: 25 - 125mm

Bend radii R: 55 - 175mm

Pitch: 46mm

Series 2700 ESD

Inner height hi: 35mm

Inner width Bi: 50 - 125mm

Bend radii R: 63 - 150mm

Pitch: 56mm

E4.1 ESD

ONE series for almost all applications

Series E4.21 ESD

Inner height hi: 21mm

Inner width Bi: 30 - 70mm

Bend radii R: 048 - 100mm

Pitch: 30.5mm

Series E4.28 ESD

Inner height hi: 28mm

Inner widths Bi: 40 - 125mm

Bend radii R: 055 - 125mm

Pitch: 46mm

Series E4.32 ESD

Inner height hi: 32mm

Inner widths Bi: 50 - 200mm

Bend radii R: 063 - 250mm

Pitch: 56mm

Series E4.42 ESD

Inner height hi: 42mm

Inner widths Bi: 50 - 200mm

Bend radii R: 075 - 250mm

Pitch: 67mm

Series E4.56 ESD

Inner height hi: 56mm

Inner width Bi: 75 - 300mm

Bend radii R: 135 - 250mm

Pitch: 91mm

Series E4.80 ESD

Inner height hi: 80mm

Inner width Bi: 75 - 300mm

Bend radii R: 200 - 300mm

Pitch: 111mm

zipper ESD

Quick to zip-open

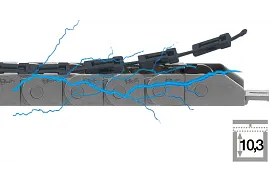

Series 07 ESD

Inner height hi: 10.3mm

Inner width Bi: 10 - 50mm

Bend radii R: 18 - 38mm

Pitch: 20mm

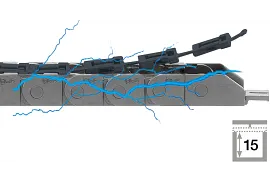

Series 09 ESD

Inner height hi: 15mm

Inner width Bi: 16 - 50mm

Bend radii R: 28 - 48mm

Pitch: 20mm

E2 micro ESD

Smallest dimensions

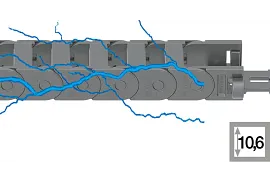

Series E2C.10 ESD

Inner height hi: 10.5mm

Inner width Bi: 16 - 30mm

Bend radii R: 18 - 38mm

Pitch: 20mm

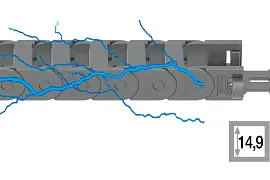

Series E2C.15 ESD

Inner height hi: 15mm

Inner width Bi: 16 - 30mm

Bend radii R: 28 - 48mm

Pitch: 20mm

E4/light ESD

Lightweight, stable and cost-effective

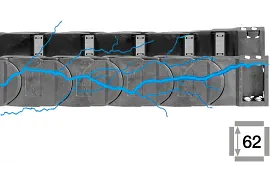

Series 14240 ESD

Inner height hi: 62mm

Inner width Bi: 50 - 200mm

Bend radii R: 150 - 250mm

Pitch: 91mm

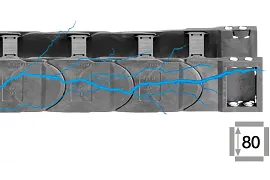

Series 15050 ESD

Inner height hi: 80mm

Inner width Bi: 75 - 300mm

Bend radii R: 150 - 250mm

Pitch: 91mm

E6 ESD

Quiet from 27dB(A), low vibration and suitable for cleanrooms

Series E6.29 ESD

Inner height hi: 29mm

Inner width Bi: 30 - 100mm

Bend radii R: 55 - 150mm

Pitch: 22mm

Series E6.40 ESD

Inner height hi: 40mm

Inner width Bi: 40 - 125mm

Bend radii R: 63 - 150mm

Pitch: 27.8mm

Series E6.52 ESD

Inner height hi: 52mm

Inner width Bi: 40 - 125mm

Bend radii R: 75 - 150mm

Pitch: 30mm

triflex® R ESD

Especially for robot applications, closed design

Series TRC.40 ESD

Inner height Bi 1: 15mm

Inner height Bi 2: 13mm

Bend radius R: 58mm

Pitch: 13.9mm

Series TRC.60 ESD

Inner height Bi 1: 22.5mm

Inner height Bi 2: 19.5mm

Bend radius R: 87mm

Pitch: 20.4mm

Series TRC.70 ESD

Inner height Bi 1: 28mm

Inner height Bi 2: 24mm

Bend radius R: 110mm

Pitch: 25.6mm

For cleanroom applications

Cleanroom-compatible up to ISO Class 1

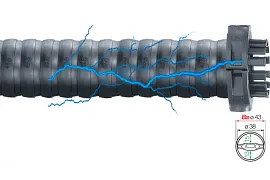

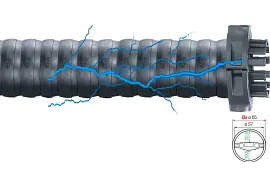

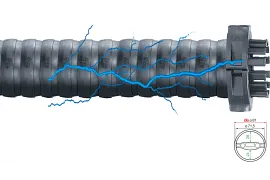

Ribbon cable e-skin flat ESD

Inner height hi: 12mm

Outer height ha: 13mm

Number of chambers: 2 - 6

Cable diameter: 10mm

Corrugated tube e-skin soft ESD

The e-skin soft ESD is suitable for the highest cleanroom classes and requires only minimal installation space. It has a self-supporting function and a closed design.

To the corrugated tube e-skin soft ESDInformation material

Material data table igumid ESD

| Material data igumid ESD | Measurement units | igumid ESD |

|---|---|---|

| Mechanical properties | ||

| Limit of elasticity (bending) | MPa | 9,500 |

| Flexural strength | MPa | 230 |

| Shore D hardness | - | 83 |

| General properties | ||

| Density | g/m3 | 1.2 |

| Moisture absorption 23/50 r.h. | - | 1.9 |

| Maximum water absorption | - | 7.3 |

| Electrical properties | ||

| Specific transitional resistance | Ωcm | <109 |

| Surface resistance ROA | Ω | <109 |

| Thermal properties | ||

| Lower operating temperature | °C / °F | -40°C / -40°F |

| Max. long-term application temperature | °C / °F | 80°C/176°F |

| Max. short-term application temperature | °C / °F | 150°C/302°F |

| Material certificates | ||

| Fire resistance according to UL94 | - | HB |

| Silicone-free | - | yes |

| Halogen-free | - | yes |

| 2002/95/EC (RoHS) | - | yes |

| 2002/96/EC (WEEE) | - | yes |

| Colour (according to RAL, approximate) | ||

| ESD energy chains, slate-grey | ≈ RAL7015 | |

| Exception: lid zipper and triflex R, black | ≈ RAL9004 |

Further information

These additional operating instructions apply to our ESD energy chains in the grey (similar to RAL 7015). They supplement the assembly instructions for standard energy chains and the details in the catalogue. These instructions only contain data relating to the ESD area. The technical specifications of the assembly instructions for standard energy chains and the catalogue details still apply unless they are excluded or replaced by these instructions.

Regarding assembly, removal and installation, please follow the instructions for the igus standard energy chains and the catalogue details to ensure trouble-free operation. igus ESD energy chains must be grounded with appropriate measures in accordance with drawing number 18392 to dissipate any occurring electrostatic charge. Assembly, installation, commissioning and maintenance may be performed only by personnel that is properly trained in explosion protection! Please also note the corresponding national safety regulations and the relevant national regulations in respect of explosion protection during installation and operation.

Before commissioning, the correct installation must be checked in accordance with the assembly instructions for standard energy chains and the catalogue specifications. Particular attention is required concerning the correct earthing of the ESD energy chain.

igus energy chains are maintenance-free*. The correct earthing of the energy chains has to be checked at regular intervals (*in the case of large projects, individual maintenance plans may be necessary and will be drawn up as required).

Flying probe tester from SPEA

Consulting

I look forward to answering your questions

Hitech UAB (Distributor)+370 37 323271Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr